My Woodworking Projects

Welcome to my catalog of woodworking projects I have tackled. I put this together so I could remember the different projects I have built so far. I hope to keep updating this webpage as I create new woodworking projects and learn new skills. Enjoy!

Project Index, in reverse chronological order....kind

of (updated 12/22)

29. Dust

Collection (in progress)

28. Kids Hammers (Halloween)

27. End-Grain Cutting Board

26. Seam

Clapper (x2)

25. Dovetail Box (with

router jig)

24. Arcade

Cabinet

23. Sewing

Machine Table

22. Potting Bench

21. Toy Crane

20. Kids Swords

19. Tensegrity

18. Plinko board

17. King Bed

16. Built-In Cabinets

and Shelves

15. Outdoor Picnic Table

14. Hexagonal Fish

Tank Stand

13. Indoor Bench II

12. Indoor Bench (Shaver)

11. Garage Wood Storage

10. Seder Plate Box

9. Knife Block - add on

8. Mail Holder

7. Baby Cradle

6. Worktable on Wheels

5. Quilt Rack

4. Router Extension Table

3. Game Cabinet

2. Seed Planter Boxes

1. Garage Bench

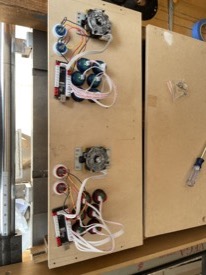

Dust Collection

Time of build: 2022-23Built for: The Woodshop (and my lungs)

Wood used: Scrap wood, and hardware bought from

home-depot and online

home-depot and onlineDescription: I finally got around to installing a dust collection system...but I didn't want it to take up much floor space in the garage. I ended up buying a Harbor Freight system and added in an Oneida chip collector to make the system a two-stage style system. I installed the blower on one of the garage shelves and vented it outside (so no bag/filter needed). One cool thing is I stumbled across these 'magport' connectors which are really cool and work out well for my shop. So I have one hose for the dust collection system that can 'easily' attach to many of the tools in the garage via the magnetic connectors.

Still futzing around with some of the tools/connections like the table saw (which required me to seal it up for dust collection and attach a magport. Definitely a fun project to get the garage setup (and another opportunity to clean things up). Hopefully will be done soon and can move onto the next project!

Kids Hammers

(Halloween)

Time of build: 2022Built for: The kids

Wood used: A leftover 6x6 beam from Shaver lake and a large chunk of red cedar my dad cut off from a stump of a previously fallen tree (also in Shaver lake). And one piece of oak that was also cut down in Shaver lake (for the handle).

Description: This one was also quite fun as it was for the kids. Originally (after a fun disneyland trip), my daughter decided she wanted to be Thor for halloween and we splurged and bought her a Thor costume. So obviously she needed a hammer. I thought it would be a quick build. My son (who wanted to help) and I found some pictures online of Mjolnir to help with some rough dimensions. The cuts were kind of tricky on the table saw as I had to construct a jig to make the cuts and the table saw blade wasn't quite big enough to make some of the cuts in one pass. To make things 'easy' I ended up using two dowels I had lying around and did some

careful

drilling to make one into a 'sleeve' for the other for the end

cap and where the dowel attached to the hammer. Stained

the head of the hammer with a gel java stain and I think it

really came out nice.

careful

drilling to make one into a 'sleeve' for the other for the end

cap and where the dowel attached to the hammer. Stained

the head of the hammer with a gel java stain and I think it

really came out nice.After the hammer was all done...that is when my son decided he ALSO wanted to be Thor for halloween. Two Thors!! Once again a costume was purchased...and the decision that he also needed something to carry. Instead of another hammer, we decided to make Storm Breaker. This one was a bit harder as we made both ends of Storm Breaker from a large chunk of red cedar and initially I had no way to cut it in the garage. Ended up cutting it by hand with a saw (Yikes...I need a bigger bandsaw :-)...or at least a better hand saw!).

I tried something a bit different by drawing and cutting grooves into the heads of the hammer in some designs and filling those grooves with wood filler to make a pattern. I think the effect came out real nice. Made the handle of storm breaker from an (originally) twisted piece of oak. Stained the handle with the gel java stain and the rest with some BLO (I think...).

What a fun build and both kids got to be Thor!

End-Grain Cutting

Board

Time of build: 2022Built for: The family and our house

Wood used: Maple and Walnut, mostly scraps (although I think I did use a board of maple I had stored away in the garage from Southern Lumber...and they closed in 2015)

Description: This one was fun for a few reasons. First...it was my first cutting board (ever), and that feels like something I should have made awhile ago. Second, my son helped design the pattern for the 'W' and then my wife gave it the thumbs up on the placement.

I created the solid maple piece first at the bottom and then the 'W' second as that was still trying to figure out the process. I originally thought I would hand plane this monstrosity down as I had read some of the dangers of planing end-grain on the thickness planer. But after reading some other articles, I decided to go for it and luckily no disaster. Definitely chose the slowest setting and took really really really shallow passes. I was fairly pleased that the top and bottom pieces (separately through the planer) glued up together fairly easily without needing much more sanding/planing on the final piece.

It is definitely heavy and I had to add some slight shim and cut things away to get it all to come together. I continued to learn patience with the many glue-ups that contributed to this cutting board. We currently use it in the kitchen. There were two areas that started to split near the edges, but I added some more glue and clamped them together and for over a year the cutting board is still going strong!

Seam Clapper (x2)

Time of build: 2022 Built for: The

wife....and then another for an auction supporting the quilt

guild the wife is a part of

Built for: The

wife....and then another for an auction supporting the quilt

guild the wife is a part ofWood used: All scraps (birds-eye maple and mahogany)

Description: Did anyone know what a seam clapper is? Answer....yes, if you work with fabric. From the internet..."It works by absorbing the steam applied to a seam, and locking in the heat. As you press down on the seam with the clapper, the pressure sets the seam flat as the fabric cools."

After I made one for the wife, she asked me to make another one for a quilt auction at one of her retreats! Can't seem to find a picture of the second one..but I think our neighbor, who is in the same quilt guild with my wife, won it!!

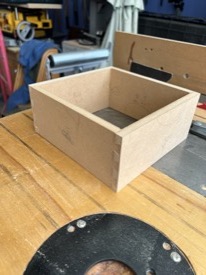

Dovetail Box

(with router jig)

Time of build: 2022Built for: Not really sure (there is a story behind this one...you have to ask in person :-))

Wood used: Scrap wood....maple, cherry, mahogany

Description: This was a 'fun' project to try to see how well the dovetail jig I inherited worked (FYI...not well). I could never get the

dovetail jig to work perfectly...although I

will say I tried with multiple blanks and test pieces.

Maybe I just need to keep trying, but even when I thought I

had it dialed in, the subsequent cuts changed just enough

where I had to try a few things to fill the dovetail joints

that didn't perfectly line up. Definitely learned a few things

including on the planer (and made a planer sled during this

project) and some more practice on glue-ups and router work.

dovetail jig to work perfectly...although I

will say I tried with multiple blanks and test pieces.

Maybe I just need to keep trying, but even when I thought I

had it dialed in, the subsequent cuts changed just enough

where I had to try a few things to fill the dovetail joints

that didn't perfectly line up. Definitely learned a few things

including on the planer (and made a planer sled during this

project) and some more practice on glue-ups and router work.I tried to plane a fairly thin piece of wood (already glued up piece) and almost had an issue with the planar after it ate one of my pieces. Overall a fun project..but probably won't be using that router jig again.

One nice outcome is my wife got a new box for holding recipe cards!

Arcade Cabinet

Time of build: 2021Built for: The kids...but also for me :-)

Wood used: MDF

Description: I saw someone had built a full size arcade cabinet recently and thought...I could do that (maybe...). After doing some research, I found a few sites describing using a Raspberry Pi to

power a MAME or FBA. I could write a

whole bunch about my fun trials to get something up and

running...but I did it! Using RetroPie and some

controllers purchased online. I did buy a screen and got

it installed in the arcade cabinet...and then in one of the

transitions the screen cracked...so I had to buy the exact

same screen as I had already installed the mountings for that

model I found an old bose speaker and custom

mounted that in the top of the cabinet.

power a MAME or FBA. I could write a

whole bunch about my fun trials to get something up and

running...but I did it! Using RetroPie and some

controllers purchased online. I did buy a screen and got

it installed in the arcade cabinet...and then in one of the

transitions the screen cracked...so I had to buy the exact

same screen as I had already installed the mountings for that

model I found an old bose speaker and custom

mounted that in the top of the cabinet.My experience with the templates and the router on the sewing machine table project helped out. I used some of the similar techniques to make sure the sides of the cabinet were the same (definitely a bit of lifting and maneuvering around on the router table...but it all worked out!).

Took awhile to settle on what the theme of the cabinet should look like. Settled on The Last Starfighter (a cool 80s movie). I found someone in England who had some arcade art that the printed out on vinyl and I applied the arcade. As an added exercise, I was able to get this version of last starfighter game (thank you roguesynapse) working using some funky PC emulation and patience. It is pretty cool to have it all working.

Sewing Machine Table

Time of build: 2021Built for: My Wife

Wood used: Birds-eye maple (Grampy's favorite) and mahogany

Description: After the potting bench and some solid garage clean up, I was looking to build something with a bit more finesse. About the same time, my wife came back from a sewing machine repair class

(offered through the person who sold her a

refurbished sewing machine) and had a pattern for a knockdown

sewing machine table that fit an older Singer featherweight

sewing machine she recently purchased. The pattern was

fairly 'simple' (or so I thought) and the project was just

what I was looking for at the time.

(offered through the person who sold her a

refurbished sewing machine) and had a pattern for a knockdown

sewing machine table that fit an older Singer featherweight

sewing machine she recently purchased. The pattern was

fairly 'simple' (or so I thought) and the project was just

what I was looking for at the time.Got to make really great use of the band-saw and router. This was the first time (in earnest) that I made templates out of mdf and used the router (with some new router bits!!) to get 'perfectly' matching and symmetric legs. I also went out and bought a nice piece of birds-eye maple as my wife really wanted a piece that used that wood to remind her of her Grandfather (who was also a woodworker and used birds-eye maple regularly). For the legs I used some mahogany leftover from the bed project. Finished the project with BLO and (I think) a top coat of polyurethane.

Very fun project and it does disassemble into flat pieces. Still trying to find an easy 'carrying case' for it so that my wife can bring it to some quilting retreats. Not sure if that will ever happen as it is a bit heavy.

Potting Bench

Time of build: 2020Built for: The garden and the family

Wood used: All reclaimed wood (and scraps from other projects)....Really!!

Description: I am really proud of this project because it used only left-over wood and scraps from the garage. Got to clear out

the garage of some

old 4x4 posts, the remaining redwood deck wood that was still

left over from the outdoor

picnic table, and even 2 doors we pulled off the house

when we moved in! I found a general plan online and

adapted it to fit the space under the kitchen window. I

had to dig up the area under the window and put some left over

pavers to make it 'flat' to start the entire project

off. My wife picked the color (we both thought the blue

would be a bit darker) and it looks great! I would love

to re-write history and say I planned to have two different

style doors to showcase something...but the truth is I forgot

to add the depth of the doors to my initial drawings and when

I put it all together the left door was blocking the

gate. Luckily the entire construction was put together

with screws (I tried out pocket screws) and I took the left

door apart and replaced it with one that was smaller and fit

inside the frame. The top is a glue-up of the leftover redwood

(barely had enough pieces to get it to size), finished with

multiple coats of Linseed Oil + Spar Urethane in different

proportions. Definitely a fun build and hopefully we

will get some good use out of it!

the garage of some

old 4x4 posts, the remaining redwood deck wood that was still

left over from the outdoor

picnic table, and even 2 doors we pulled off the house

when we moved in! I found a general plan online and

adapted it to fit the space under the kitchen window. I

had to dig up the area under the window and put some left over

pavers to make it 'flat' to start the entire project

off. My wife picked the color (we both thought the blue

would be a bit darker) and it looks great! I would love

to re-write history and say I planned to have two different

style doors to showcase something...but the truth is I forgot

to add the depth of the doors to my initial drawings and when

I put it all together the left door was blocking the

gate. Luckily the entire construction was put together

with screws (I tried out pocket screws) and I took the left

door apart and replaced it with one that was smaller and fit

inside the frame. The top is a glue-up of the leftover redwood

(barely had enough pieces to get it to size), finished with

multiple coats of Linseed Oil + Spar Urethane in different

proportions. Definitely a fun build and hopefully we

will get some good use out of it!

Toy Crane

Time of build: 2019?Built for: My Son!

Wood used: Maple, Poplar, and Ironwood

Description: I found this plan and it looked cool! My dad was building some wood toys near the same time and I thought I would try my hand at it with this crane. It was pretty fun and the knobs raise/lower the boom and the rope. I don't have a lathe so I cut the wheels using methods that were not super precise, but overall it came together and my son said he loved it. I would call this one a success given the customer was happy!

Kids Swords

Time of build: 2019?

Built for: Fun!

Wood used: Plywood scraps

Description: My son is great at drawing and drew some sword outlines on some pieces of wood. We decided to use the bandsaw to cut them out and make some swords. Definitely a fun process and the kids love playing with the swords in the backyard. Sometime later the kids painted their swords....although I don't have any pictures!

Tensegrity

Time of build: 2019?Built for: Fun!

Wood used: Scraps

Description: I saw this on some of the woodworking forums (e.g. tensegrity table). Thought it would be fun to build one out of scrap wood and see if it made sense to make something more 'fancy'. Definitely pretty cool, but haven't decided to make anything more for now.

Plinko Board

Time of build: 2017Built for: The Purim Carnival (temple preschool)

Wood used: Plywood

Description: A quick build for a pre-school sponsored event. Two pieces of plywood attached together with a hinge to make it "easy" to fold and transport. My dad was nice enough to turn the discs. Another volunteer was responsible for painting. Lots of individual dowel pegs cut, drilled, and glued in place. It has been awhile since the build, but I think I used a hand jigsaw to cut the curves on either side. Take a look at this video of it in action!

King Bed

Time of build:

2016-2020 (Yikes!! this one took awhile)Built for: My Wife (and me too!)

Wood used: Mahogany, Walnut, Maple (plywood)

Description: This was definitely a labor of love (also of sweat, time, and much learning). My wife was interested in getting a headboard for our previous bed (circa 2016) to have a real 'adult' bed. I thought it was also time to try my hand at making a bed and said I could probably finish it up by the end of 2017 at the latest. Four years later....the 'decade of the bed' was over and we have been enjoying restful sleep ever since. I found some inspiration of the design from some pictures of online and decided to try making it my own. Several anecdotes throughout this build:

- Our local hard wood store went out of business and I bought a bunch of mahogany to help finish this project

- I originally thought of trying to use birds-eye maple veneer (in honor of Jenny's grandfather who used birds-eye maple in some of his woodworking projects) on the large panels (even bought some veneer and glue). But after some failed attempts with trying out the veneer process on smaller pieces and having not great looking results, I gave up and bought some nice maple plywood.

- The staining process was quite involved (I tried something from a Wood magazine). Essentially creating a slurry by sanding in the stain/finish with progressively increasing grit. I don't even remember the process at this point, but still have the magazine if I ever decide to go back to try it again. I think the final coat was some clear wax (Bison brand?).

- The bed took so long that there were several times when

I wrapped up all the pieces (at different stages and put

them away for several months at a time) just to make room

for other projects

Built In Cabinets and Shelves

Time of build: 2015-2016Built for: The House, Add on room

Wood used: Plywood and Wood easily painted

Description: We enclosed an outside patio area into an additional room for the house and we "commissioned" this built-in with my Dad. My wife drew out the shelving specific for hanging quilts and displaing some of the wood trucks my Dad had previously built. It has been awhile, but I recall my Dad came up and installed the base/cabinets that he had pre-built at his house. He also had cut out the top shelving pieces. Unfortunately time ran out and he got as far as he could before he had to go back home (sometime around Thanksgiving/Christmas). I was tasked with finishing it all up! It came together pretty quickly, but then filling in the gaps, painting, and making some custom pieces to fit the non-square walls of our house took some time. I really like the look of it and it really matches the room (particularly the barn doors that were installed by the contractor when the room was added to the house).

Outdoor Picnic Table

Time of build: 2015

Built for: The Family!

Wood used: Repurposed from redwood deck

Description: This one took quite some time! We

started by pulling up an old deck in our backyard and

storing the wood along the side of the house. The wood sat

for quite some time and then with the help or my jointer and

my dad's planer, we were able to get the wood to a point it

was usable for a project like this. I got the plan from a

Wood Magazine and I think it really came together

nicely. My wife arranged the top boards so the

color/grain made a nice pattern. The finish is a combination

of Linseed oil, Spar Urethane, and Mineral Spirits (varying

amounts depending on the coat). I like how things came

together, although it definitely took longer than I

thought. This big project was a bit unwieldy to work

on in the garage but I am very glad it is now in our

backyard and available for use!

Hexagonal Fish

Tank Stand

Time of build:

early 2014

Built for: The Fish...

Wood used: Leftover plywood

Description: We had an old fish tank from Jenny's

childhood and were looking to upgrade. Luckily my

brother and I had given my mom a fish tank to grow orchids

when we were young and she didn't want it anymore. We

repurposed her "orchidarium," but we needed a stand for the

hexagonal tank. This custom design is fairly simple

and matched the base of the fishtank. I did practice all the

miter cuts on a smaller version to get the angles just

right. I made one of the sides into a door and I think it

came together fairly nicely. I used a dark stain (not the

Java...something slightly lighter that I don't remember the

name of). As a bit of a decorative touch (and because Jenny

kept saying the stand needed to be strong and not fall

apart...), I added two maple splines to each of the miter

joints. The splines extend to one side door and

"match" up when the door is closed. A fun project!

Indoor Bench II

Time of build: mid

2013

Built for: My Wife

Wood used: Cherry and Maple

Description: The Shaver Bench was my

downfall. Jenny liked it too much and wanted me to

make something similar for our master bedroom...with a few

modifications). First she wanted it to look nice(r).

Second she wanted it to be able to have storage for large

containers underneath. Third she wanted it to look nice. I

liked the look of the two contrasting woods with the Shaver

Bench, but wanted to do something a little cleaner (not sure

what I mean by this...but this was a thought going through

my head). I decided on Maple and Cherry, as I had good

success with those woods when I built the cradle. I measured

out the bench requirements and first found out that all my

13/16" Maple was too short. I could either get fancy, or buy

more wood. Being cheap, I decided to 'bookend' the

center of the bench with maple running with perpendicular

grain. The end product looked pretty good, but getting

the glue up to look as good as I wanted was not trivial.

From the Shaver Bench experience, I decided I didn't want to ad-hoc the bottom structure, so I built the whole thing on a piece of sturdy plywood. I added an extra deep cherry lip to the front so it looks like the solid wood I used for the bench top is thicker than it really is. Instead of using the jointer, I just cut all the pieces on the table saw. That saved time and still made the glue-ups line up.

I am proud of the supporting structure underneath the

bench. I originally planned on bracing the bench on

three sides and only putting a backer on each wall the bench

would rest against. This way the bench wouldn't have

any legs and Jenny could have all the storage space she

wanted. Unfortuantely, once we put the bench on the backers,

it looked good, but there was a substantial deflection of

~1/8" in the center front when we sat on it. The whole thing

didn't feel sturdy. So, with the help of my Dad, we build

some supporting struts that we connected to the front of the

bench that extended at an angle and connected to the back

wall. After tightening some things down, the bench

feels solid, has a clean look, and Jenny has her storage

space. I finished the whole thing with water-based poly

applied using my Harbor Frieght HVLP sprayer my Dad got for

me as a gift.

Indoor Bench (Shaver)

Time of build:

early 2013

Built for: My Mom

Wood used: 13/16" maple (assorted widths I usually

get from Southern Lumber), random cedar from a tree my

parents cut down in Shaver, more maple for the legs

Description: This project took awhile to get off

the ground. It started because my mom wanted to have a

different bench in their Shaver Lake home. After some

drinking, I said I could make a bench if they gave us their

old bench (cast iron sides with wood slats). It seemed like

a good trade as we got a bench right away! My Mom laid

out the rough shape she wanted the bench to have in the

foyer area and she taped and cut out some newspapers so I

could take that rough shape home.

I designed the entire thing from the rough shape, building

the top first. I wanted to try something new, so I decided

to incorporate some of the cedar logs my parents had given

me from a tree they cut down into the bench. I settled

on making 1.5" x 8" blocks that I incorporated in the glue

up of the top. The top was done in two separate pieces, the

long ~8' part and the shorter ~3' curved part. I used the

jointer  to get all the edges of the individual glue

ups nice and flush (some hand work here and there). To get

the two glued up pieces together, I clamped them down and

used the router to cut them simutaneously in one pass. This

was not easy, but the different orientation of the wood did

end up gluing up ok. I probably over-built the legs and

support structure, but I didn't want it to fall apart. The

picture to the left is the bench in the master bed room at

home...Jenny wanted to see how a bench would look there and

whether or not I should be making something for our home

(that was the start of the Indoor Bench II project). The

bench was finished with water-based polyurethane (probably

could have put more on than I did).

to get all the edges of the individual glue

ups nice and flush (some hand work here and there). To get

the two glued up pieces together, I clamped them down and

used the router to cut them simutaneously in one pass. This

was not easy, but the different orientation of the wood did

end up gluing up ok. I probably over-built the legs and

support structure, but I didn't want it to fall apart. The

picture to the left is the bench in the master bed room at

home...Jenny wanted to see how a bench would look there and

whether or not I should be making something for our home

(that was the start of the Indoor Bench II project). The

bench was finished with water-based polyurethane (probably

could have put more on than I did).

Overall I am pleased with how it turned out. Once again I learned a lot (probably mostly forgotten now). It was great to incorporate some lumber from a tree my parents cut down and the low profile of the bench is exactly what my Mom wanted. Fun project...now that it is done.

Some pictures from when I just put the bench together in

the garage...

Wood Storage - Garage

Time of build: ??

not sure

Built for: The Garage

Wood used: Leftovers

Description: I needed a place to store some wood

in the garage. Floor space is at a premium so I

decided to build some overhead wood storage. As

always, this project is probably over built...but I didn't

want any wood crashing down onto my head! It works

really well and I can use either my ladder or the worktable

on wheels to easily get access. Now I have no problem buying

the "cheap" 13/16" maple at Southern Lumber and storing it

myself so I can start a project with it any time.

Seder Plate Box

Time of build: mid

2012

Built for: The Seder Plate

Wood used: Poplar

Description: Jenny and I got a Seder plate on our

visit to Turkey. Jenny wanted me to make a box so the plate

would be safe. Unfortunately, the box if functional but

didn't turn out as nice as I wanted. I built a finger joint

jig for the router

to construct this box and that worked fairly well. The

finger joints came together nicely (maybe a little tight to

start), and I was generally pleased with the look of the box

I designed. However, staining once again was an issue.

The first go around I decided to use an old stain that I had

lying around. It turned the nice box into a blotchy

mess. UGH!! Why do I do this?!! We used the box

for awhile, but every time I looked at it I was ashamed. I

got fed up and resanded it a bit and tried to salvage the

look of the Seder box with a darker stain (the General

Finishes Java). It improved the look quite a bit...not as

good as I would like, but now good enough where I don't

cringe everytime I look at it. Lesson learned....at least

until I want to finish off an old can of stain on a "side"

project.

for the router

to construct this box and that worked fairly well. The

finger joints came together nicely (maybe a little tight to

start), and I was generally pleased with the look of the box

I designed. However, staining once again was an issue.

The first go around I decided to use an old stain that I had

lying around. It turned the nice box into a blotchy

mess. UGH!! Why do I do this?!! We used the box

for awhile, but every time I looked at it I was ashamed. I

got fed up and resanded it a bit and tried to salvage the

look of the Seder box with a darker stain (the General

Finishes Java). It improved the look quite a bit...not as

good as I would like, but now good enough where I don't

cringe everytime I look at it. Lesson learned....at least

until I want to finish off an old can of stain on a "side"

project.

Knife Block - add on

Time of build: mid

2012

Built for: The Kitchen

Wood used: Poplar

Description: Jenny gave me a fancy knife for my

birthday in 2011 (it took awhile to get around to this

project). We were happy with our current knife set and

wanted an easier way to store the new knife. I

extended the knife block with a new slot on the top. To get

all the wood to match, I restained the entire knife block

using the General Finish - Java stain I saw as being

recommended from some wood working show or magazine.

It turned out great and we are still using the knife block

today!

Mail Holder

Time of build: mid

2012

Built for: Mail Storage

Wood used: Poplar

Description: Our mail kept piling up on the

kitchen table and we didn't have a great place to store

bills that we didn't want to pay right away. I

designed this simple mail holder so we could put it on a

counter/desk and keep our mail organized. There is a

slot for me, Jenny, bills and mail waiting to be sorted. Fun

project as I got to use the router to make most of the

joinery. No screws or nails, just glue. I took a couple of

pictures while the project was unassembled so I could

remember the joints I used.

Baby Cradle

Time of build: Late 2011, early

2012

Time of build: Late 2011, early

2012

Built for: My Son

Wood used: Maple and Cherry, Walnut pins

Description: This was truly a labor of love.

I am not sure if all new expecting parents go through this,

but once we knew about Nathan, I really started fixing (or

learning to fix) things around the house. I believe this is

why all Dads know how to fix things...because they do so

much of it before their children are born. I also wanted to

build something for Nathan an Jenny suggested a cradle. The

sides and bottom are made from 13/16" maple boards (assorted

widths) that I got from Southern Lumber. The maple was

surfaced on two sides and had one clean edge. I like the

clean look of maple and getting the wood this way makes it a

lot cheaper. I found this plan (not sure

from where) and really liked the look of it and that the

cradle easily swung back and forth. The dovetails are cut by

hand (they are hard and I need to get better at cutting

those). I really worried I would mess up the workpieces

badly, but after practicing a few times on some blanks, I

think they turned out well. I don't have a lathe, so I had

my Dad turn all the spindles (Thanks Dad!). Nathan used this

cradle for the first couple months of his life, but pretty

quickly out grew it (he was a really really big baby). We

pulled it out again for Dani and she got to use it too!

Jenny now keeps the cradle in her quilt room to store yarn,

so at least it still gets some use and is not stored away in

the attic collecting dust.

Worktable on Wheels

Time of build: mid

2011

Built for: Me!!

Wood used: left over 3/4" plywood, left over mdf,

craigslist-found tabletop

Description: This project was quite a bit of fun to

build. I used mostly recycled materials and now I have a

worktable on wheels that gives me quite a bit of flexability

on building things in the garage. I use it in some way or

another for large projects and small everyday fix-its. I

found the plan from a this book

I picked up at a garage sale. One of the neat things

about this build was more practice with frame and panel

doors and a really neat way to make drawer joinery using

only the table saw. I found the table top free on craigslist

for an easy laminate surface to work on. I adjusted

the plan (slightly) so I could use this table as an outfeed

table for my table saw. The drawers and cabinets also open

from both sides. I put a vise on one side which has also

come in handy. A great garage worktable!

Quilt Rack

Time of build: late

2010

Built for: My Wife

Wood used: Poplar, cherry spindles, plugs and

buttons

Description: My wife is an amazing quilter.

I have spent more than my fair share of time in quilt

stores, quilt festivals, and fabric shops. She

actually presented me a quilt she had made for me on our

wedding day in front of all our guests. Only naturally I

would eventually make her something to help display her

quilts. I searched for something to make her and came across

this wall

mounted quilt rack plan. This project actually came

together fairly easily. The adjustable shelves are a nice

feature and the cherry plugs and buttons really highlight

the light color of the poplar. Some of the smaller

parts I made by hand while the decorative sides I rough cut

with a jigsaw and cleaned up by hand. Once again I used

poplar, but this time I searched through the stack to get

poplar that was uniformly lighter in color (no brown/green

spots). After the fiasco with staining, I only used a clear

top coat of polyurethane and let the wood speak for

itself. I think it turned out well and the quilt rack

is now hanging in our bedroom with several of her quilts on

display, including the quilt she gave me for our wedding

when it is too warm to use on our bed.

Router Table Extension for

Table Saw

Time of build:

early 2010

Built for: Me!!

Wood used: left over 3/4" plywood from the Garage

Bench project and Game Cabinet

Description: My Dad gave me my grandfather's

router (an old craftsman) to help populate my garage with

tools. He said it was scary to use. He was right. So I

built an extension to my table saw and replaced one of the

cast iron pieces with a router extension table. It

works great. The picture to the right shows the router

extension table on my "new" Unisaw (also a Delta product),

although I originally built it for my Delta contractor table

saw (which I sold after I picked up the Unisaw from a

friend). The router extension table is great and allows me

to use the table saw fence (with another attachment I built

for routing). I recently got a nicer router (not as scary),

but I still use the router table I built. As my

garage/workshop is not very big, it has been nice to have

the table saw double up as a router table.

Game Cabinet (Shaker Storage

Cabinet)

Time of build:

mid-late 2009

Built for: Inside storage

Wood used: 3/4" plywood, poplar (face frame and

doors), maple (glue-up top)

Description: Although the garage bench was my

first project, this was my first REAL project for inside our

house. I wanted to build something I could be proud of

looking at everyday and that was also functional and that we

could use everyday. I think I succeed with one of those. Our

house doesn't have much built-in storage and we were storing

all our board games out in the garage. I came across

this Shaker

Storage Cabinet article, liked the overall design, and

decided to take on the project. I had just started getting

excited about woodworking and had purchased an older Delta

Contractors table saw and wanted to test it out (after

spending quite a bit of time tuning it up). Almost all

the cuts and joi nery for this project were done on the table

saw. This project taugh me quite a few things...mostly what

not to do. I learned about glue-ups, frame and panel doors,

face frames, and staining (errrr...staining!!). As I was

just starting out, this project was a nice introduction to

using hardwoods (poplar is nice and cheap). As you will

notice, in the original article, the cabinet is painted. In

my infinite wisdom, I decided to try and stain my cabinet (I

like the look of wood grain and thought my cabinet w

nery for this project were done on the table

saw. This project taugh me quite a few things...mostly what

not to do. I learned about glue-ups, frame and panel doors,

face frames, and staining (errrr...staining!!). As I was

just starting out, this project was a nice introduction to

using hardwoods (poplar is nice and cheap). As you will

notice, in the original article, the cabinet is painted. In

my infinite wisdom, I decided to try and stain my cabinet (I

like the look of wood grain and thought my cabinet w ould have a cleaner look not being

painted). I was very happy with the final construction and I

was even excited enough to take a few pictures of the

mortise and tenon joinery I used when making the face frame

along the way. However, I definitely jumped too fast into

the staining. I decided to use an all-in-one stain and

sealer. I applied it to the frame and panel doors first and

after letting it dry, realized it was ugly. I spent

quite a bit of time sanding it back down and tried again. I

used a different all-in-one stain and sealer, but didn't get

much better results. By this time, I was pretty fed up with

the project and was too tired of sanding. I still don't like

the look of the blotchy stain, but we use the cabinet

everyday and it is quite functional. From this experience, I

now believe at least as much time should be spent preparing,

staining, and applying a top coat as cutting and buildin

ould have a cleaner look not being

painted). I was very happy with the final construction and I

was even excited enough to take a few pictures of the

mortise and tenon joinery I used when making the face frame

along the way. However, I definitely jumped too fast into

the staining. I decided to use an all-in-one stain and

sealer. I applied it to the frame and panel doors first and

after letting it dry, realized it was ugly. I spent

quite a bit of time sanding it back down and tried again. I

used a different all-in-one stain and sealer, but didn't get

much better results. By this time, I was pretty fed up with

the project and was too tired of sanding. I still don't like

the look of the blotchy stain, but we use the cabinet

everyday and it is quite functional. From this experience, I

now believe at least as much time should be spent preparing,

staining, and applying a top coat as cutting and buildin g. I also have learned to really test out

the stain on some scrap pieces before jumping all-in and

regretting my decision later. I also learned that not

all hardwoods are equal and that poplar is a difficult wood

to stain and could really benefit from applying some type of

pre-conditioner. This may be one reason why the cabinet in

the original article was painted. Someday my cabinet may

move out to the garage and live its life outside as a place

to store odds and ends. For now, it remains in our

house and a reminder to me to be patient and not rush

through a project (easier said than done!).

g. I also have learned to really test out

the stain on some scrap pieces before jumping all-in and

regretting my decision later. I also learned that not

all hardwoods are equal and that poplar is a difficult wood

to stain and could really benefit from applying some type of

pre-conditioner. This may be one reason why the cabinet in

the original article was painted. Someday my cabinet may

move out to the garage and live its life outside as a place

to store odds and ends. For now, it remains in our

house and a reminder to me to be patient and not rush

through a project (easier said than done!).

UPDATE - 2013, We redid our living room and the Shaker

cabinet has made the move out to the garage. It is a nice

storage cabinet for my tools and other garage items. No hard

feelings! I am glad it lasted as long as it did

inside.

Seed Planter Boxes

Time of build:

early 2009

Built for: My wife

Wood used: left over 3/4" plywood from the Garage

Bench project

Description: These simple planter boxes for

starting seeds were nothing special. Most of the cuts

I was able to do with my mitre saw. No fancy joinery,

just butt joints and screws. They have served us well and

several crops have been started in these small boxes. A

quick project that used some leftover wood and made my wife

happy. Happy wife = Happy life!

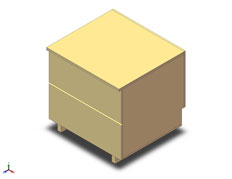

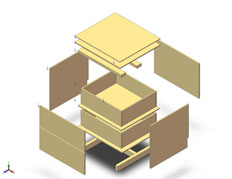

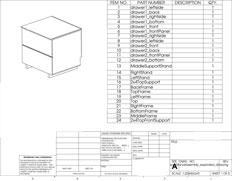

Garage Bench (my first real project)

Time of build: late

2008 - early 2009

Built for: Garage storage and a place to put my

compound mitre saw

Wood used: 2x4s, 3/4" plywood, 1/4" hardwood top,

1/2" mdf drawer fronts

Description: This 2-drawer bench has oversized

drawers to fit my toolbox and other random tools. Following

my father's advice, I built this bench with enclosed drawers

to have storage protected from the sawdust that would

eventually get produced in the garage. I got to build part

of this project with my brother when he was visiting, and I

learned it is always better to have another set of hands

(e.g., Chris, hold this finishing nail while I take a whack

at it with this framing hammer...). When you don't know what

you are doing, it is also good to have someone else around

to talk some things through. I designed the bench in

Solidworks and it stayed fairly consistent with my initial

drawings. The top was sized to the mitre saw (my only real

tool at the time). While I was away at work one day,

my Dad made and installed custom drawer handles from

leftover 2x4 pieces (Thanks Dad).

Some of the original SolidWorks pics and plans:

©2020 David W. Wagner